Manure to Renewable Natural Gas: The Economics of Anaerobic Digesters

One big question: How is renewable energy produced from dairy cow manure, and does it make economic sense?

The short answer: Manure can be processed in an anaerobic digester (AD) designed to efficiently break down organic matter (OM) and capture the resulting methane (CH4) for use as a steady, non-fossil energy supply, providing substantial revenue and numerous other benefits.

Break it down: Literally! Anaerobic digesters are either heated vessels or covered lagoons (in warmer climates) that provide an ideal environment for a set of bacteria to flourish in the absence of oxygen. These bacteria break down manure or other OM (e.g., food waste and wastewater biosolids) releasing biogas, comprised mostly of CH4, and remaining effluent, called digestate.

The captured biogas is cleaned and processed to provide fuel for a variety of renewable energy options, including:

- Electricity and recoverable heat generation using reciprocating engines, turbines, or fuel cells;

- Heat generation using boilers;

- Renewable natural gas (RNG) that is injected into utility pipelines; and

- Vehicle fuel as compressed RNG.

- Liquid fertilizer for cropland;

- Cattle bedding from separated solids;

- Compost or soil amendment with separated solids treatment;

- Irrigation with separated liquid treatment; and

- Other products with additional processing (e.g., biocrude oil, building materials, plant pots).

Economics of On-Farm Anaerobic Digestion

The 2022 U.S. Inflation Reduction Act (IRA) established substantial tax credits, currently 30 to 50 percent, that can be directly monetized for anaerobic digesters and associated “qualified biogas property”. The IRA also appropriated $300 million to USDA to expand climate-smart agricultural practices through producer incentives. There has never been a better time to evaluate the economic feasibility of an AD system!

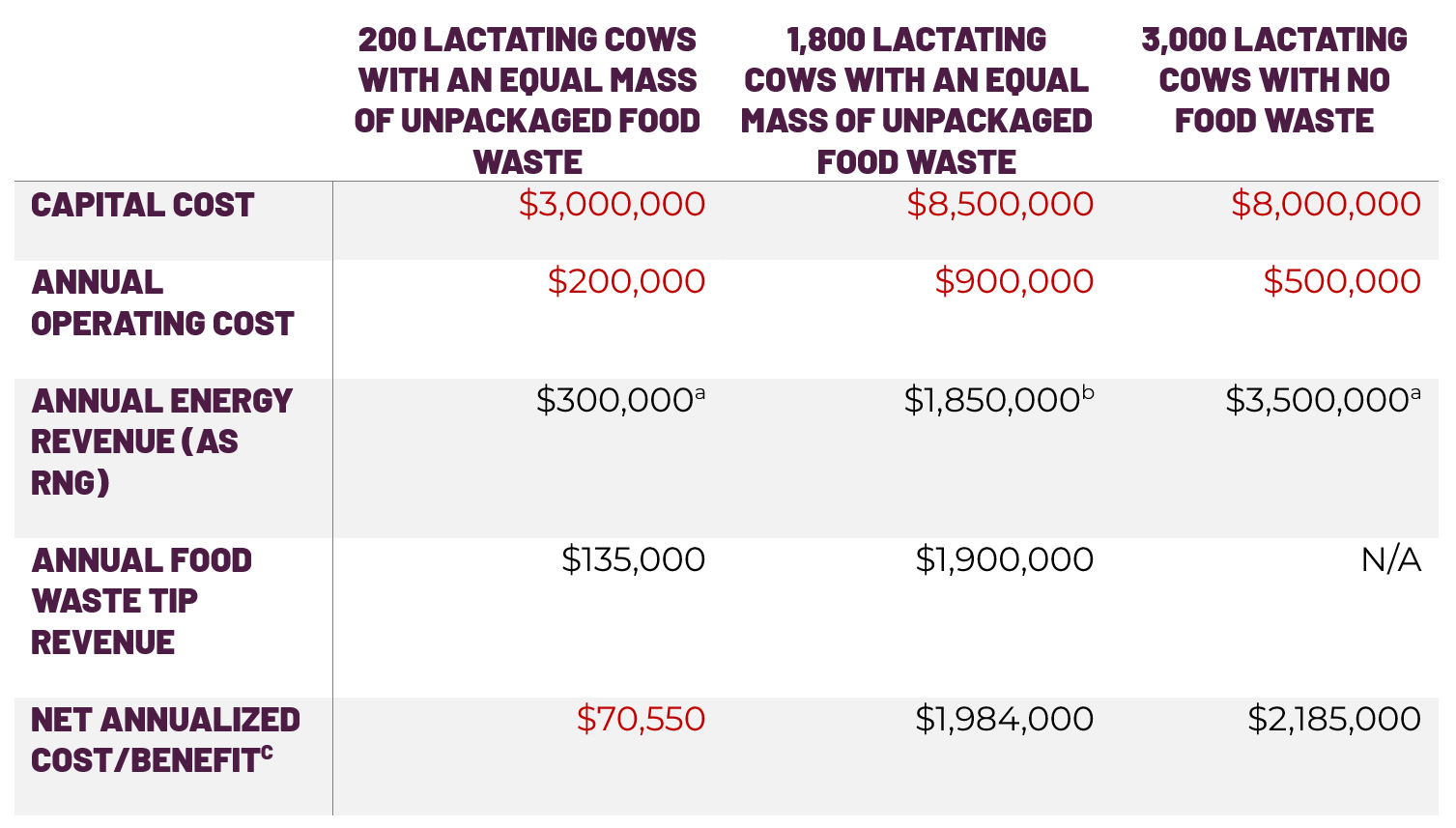

The capital cost of AD systems can vary considerably based primarily on size and type, but also on system capabilities.

- For example, an AD system that can take in food waste, especially packaged food waste, in addition to manure will cost more than one that cannot.

- However, that “co-digestion” system should bring in more revenue; food waste tipping fees and additional energy generated (food waste can often yield 2 to 3 times more energy per unit mass than dairy manure).

The table below lays out the potential economics of a few scenarios of different sized dairy manure-based, vessel-type AD systems, excluding the impact of tax credits or other capital incentives.

a Includes U.S. EPA Renewable Fuel Standard (RFS) Renewable Identification Number (RIN) value.

b Does not include U.S. EPA RFS RIN value; assumes third party buyer.

c Using an 8% discount rate over a 20-year life.

(Editor’s note: For the scenario including 200 cows with food waste, the energy revenue and tip revenue are conservative. The $3 million capital cost is realistic for producing renewable natural gas and would result in a net annualized cost. However, the 30-40% tax credit would tip the cost to an annualized benefit.)

Social and Environmental Benefits

It takes just five lactating Holstein cows’ manure to power a typical U.S. home all year!

An AD system often produces more energy than the farm needs, even when using dairy manure alone, resulting in a net renewable energy source the local community can benefit from.

- Reduced odor: Anaerobic digesters reduce the odor of the manure through the sealed degradation process, improving neighbor relations both near the farm and where the digestate is stored and land applied.

- Diverted food waste: These systems also offer a means of diverting community food waste from landfills and recycling it into substantial energy and nutrient-rich digestate.

- Nutrient retention: The valuable nutrients in manure (and food waste): nitrogen (N), phosphorous (P) and potassium (K), are retained after AD while the improving homogeneity and pumpability. There is a shift of some of the organic-N to ammonium-N after AD, so best practices to prevent ammonia volatilization are important.

Release of CH4 as a potent greenhouse gas that occurs mainly from the storage of untreated liquid or slurry manure is prevented with manure AD treatment. Methane emissions from dairy manure management has more than doubled from 1990 levels, making up 9% of U.S. anthropogenic CH4 in 2021, so steps to curb this trend are important.

What Could Go Wrong?

This all sounds good, but there is a lot to consider with a complex and capital-intensive system like anaerobic digestion.

Key considerations when planning a successful project include:

- Suitability and security of digester feedstock(s);

- Practical and economic plan for digestate handling, considering the nutrients and volume;

- Experienced partners in design engineering, equipment supply, construction, and operation;

- Securing robust agreements for compensation from energy and other project revenue sources; and

- Community perception and education.

In short: While anaerobic digestion has multiple benefits for the farm, climate, and community, it is not a fit for every farm. Now is an excellent time to review the opportunity given the available tax credits, USDA incentives, and state and federal fuel standard programs.

Photo by Lauren Ray.