Could Worms Help Cut Emissions from Dairy Waste?

This article is adapted from a technical report first published on May 4, 2022, in the Journal of Environmental Quality titled “Efficacy of a vermifilter at mitigating greenhouse gases and ammonia emissions from dairy wastewater.”

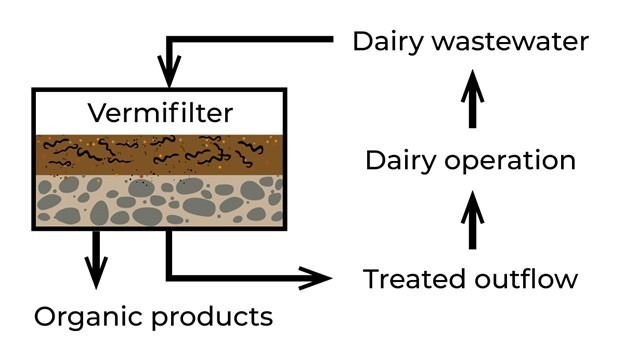

The short answer: It is possible! Vermifilter systems can use “composting” earthworms (e.g., Eisenia fetida or Eisenia andrei) and microbes to feed off of dairy wastewater, effectively converting the nitrogen and phosphorus into useful solids (more earthworms, earthworm casts) instead of greenhouse gases.

Back it up: What is a vermifilter system?

Top row: Vermifilter systems in several different locations. Middle row: BIofiltro logo, a vermifilter bed with organic material covering the worm layer, and sprinklers distributing effluent on the vermifilter surface. Bottom row: Biofiltro vermifilter system, a vermifilter bed with sprinklers, and worms in the system. Photos courtesy of Gilbert Miito.

A vermifilter system is a closed metal box that contains a sprinkler system, an organic layer, and a filtration layer. It can be a useful tool to help treat dairy wastewater, pulling valuable nutrients from the waste and capturing them as organic matter before they become greenhouse gases.

- Inside the box, a sprinkler system pumps in dairy wastewater, dripping a steady supply of nutrients over soil, earthworms, and microbes in the upper layer.

- Just below the sprinklers, an organic layer of soil, earthworms, and microbes acts as the water treatment. The earthworms and microbes feed on the nutrients from the dairy wastewater.

- The bottom layer contains a coarse filtration media like small rocks and cobblestones filters the treated water as it drains out of the box.

- Treated water drains out of the bottom of the box. This water may be stored, used for irrigation, or recycled back into the manure collection operation.

Taken together, this technology is referred to as vermifiltration.

A vermifilter can use composting earthworms to treat dairy wastewater, recycle nutrients, and provide organic products such as fish bait and soil-amending casts. Graphic by Marie Johnston.

Break it down: How can it help cut emissions from dairy effluent?

- Inside the vermifilter system, living organisms are at work transforming the nutrients in dairy wastewater into energy and biomass.

- Earthworms help both biological and chemical processes along by consuming wastewater organic materials and creating air spaces through their burrowing.

In a test of a vermifiltration system at Washington State University, researchers compared the amount of nutrients in inflow wastewater, outflow drainage, and surface emissions.

- They found that vermifilter systems perform with nearly 100% efficiency.

- Nitrogen, for example, was retained as earthworm biomass and other organic solids, instead of being released as methane and nitrous oxide gases.

How can you get started? Vermifilter systems take some planning and coordination to implement on a dairy farm, but a single unit may have long-term payoffs in terms of nutrient capture successfully adapted this vermifiltration system for industrial wastewater treatment, specifically targeting wineries, dairy farms, food processing plants, and sanitary systems.

- Manure handling: Before you start, you need a manure handling system in place to separate liquids and solids.

- Monitor conditions: You also need a way to monitor the conditions inside the vermiculture unit. Researchers at WSU used a digital thermometer and wireless telemetry monitoring platform to track pH, flow rate, dissolved oxygen, and oxidation-reduction potential.

- Small scale: For small operations, creating a “do-it-yourself” system may be most cost effective. The size of the system depends on the amount of water you want to treat. Materials include wood chips, a water-tight container (like a shipping container), IBC totes, PVC liner, and composting earthworms.

- Large scale: Biofiltro, a Davis, California-based company, has adapted this vermifiltration system for industrial wastewater treatment, specifically targeting wineries, dairy farms, food processing plants, and sanitary systems.

Once it’s up and running, the full dairy operation would be a home to a whole new community of small, wriggling compost makers!

Photo by Dan Brekke on Flickr.